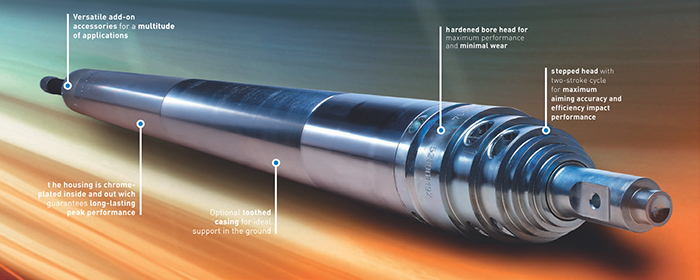

moling equipment

The benefits of Trenchless Moling

Moling technology is widely-used and ever increasing in the civil engineering fields. Compared to open-trenching this method of underground installation and renewal of supply and disposal pipelines has major technical and economic advantages. Shorter construction times is a major advantage; especially when providing property service connections like fibre installations or electrical cabling and when crossing busy roads.

GRUNDOMAT soil displacement technique

The pneumatically driven hammers work according to the soil displacement method: when moving forward the spoil is displaced into the surrounding soil. A channel is produced into which plastic (PE, PVC or PE-X), socketless short- or long- pipes up to OD160 or cables can be pulled through. Depending on the type of soil, lengths of up to 25m can either be pulled in simultaneously or later. A compressor with 6 – 7 bar operating pressure is required for this, with exact alignment of the machine towards the target necessary for high accuracy.

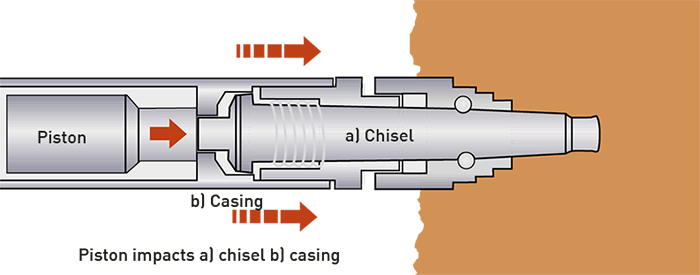

The 2-Stroke Principle

With the proven 2-stroke principle, the precise target accuracy as well as the exact alignments and adjustments are achieved through the 2-stroke impact method.

On the first stroke, the whole moving head assembly is propelled forward as the piston accelerates and impacts against the rear of the chisel driving it forward to create a pilot bore hole. As the piston then returns in the second stroke, the compressed spring in the head further pulls the long cylindrical casing into the previously made pilot bore hole.

Should an obstacle be encountered and forward propulsion hindered, the chisel or crowned head in the reciprocating head will continue chiselling independently until the obstruction is fragmented and displaced.

This makes the GRUNDOMAT achieve on- target results even in stony grounds.

Applications & Advantages

UNDER CROSSINGS

Road crossings and property service connections are everyday tasks for the GRUNDOMAT.

PIPE RAMMING FROM MODEL 130

GRUNDOMAT can also be used for ramming in steel pipes by attaching a special ram cone to the head of the machine.

PIPE BURSTING FROM MODEL 95

Modified soil displacement hammers are also applicable for pipe renewal using the pipe bursting method.

PILING

GRUNDOMATs are also ideal for vertical use such as piling for laying foundations.

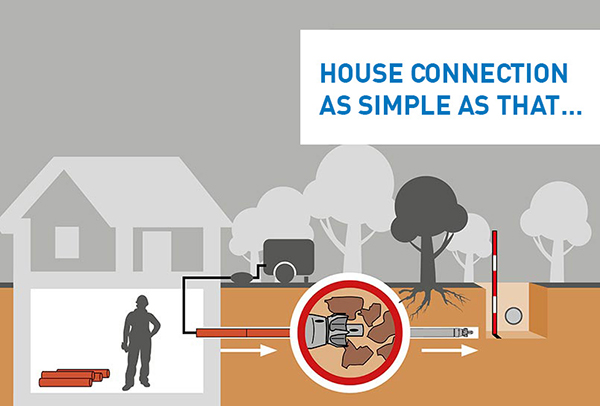

PROPERTY SERVICE CONNECTIONS – DIRECTLY FROM INSIDE THE BUILDING

When house connections for gas, water, sewage, electricity, broadband cabling and fibre can start directly from the property a start trench outside the property wall is no longer necessary. This makes the use even more efficient, and the front garden is spared.

The following applications are possible with the Grundomat

- Property service connections

- Crossings beneath roads, pavements, streams and railways

- Steel pipe jacking

- Renewal of steel pipes

- Driving out old steel pipes

- Pipe bursting measures

- Short vertical bores for laying foundations

- Anchoring bores

Advantages of the Grundomat

- Solid quality thanks to elaborate tempering processes

- Long service life, low wear, robust and durable

- Solid quality of head, piston and housing achieved through elaborate tempering processes (hardening, chrome-plating and zinc-plating)

- The main casing is precision honed internally– a fine cutting machining process which improves dimensional and formal precision

- No start-up problems thanks to the low friction of the running surface of the piston/seals

- Tight air sealing

- Low air consumption

- Easy and quick to maintain

- Rapid replacement of the head and rear fittings

Reliable Technology

- Choice between crowned or stepped head

- Optimal adaptation to the soil and ground conditions

- Two forward-gears with different impact frequencies

- Improved operational performance in alternating soils

- The two-stroke principle

- High on-target precision in different soil conditions, especially in rocky soils

- Switching-over to reverse gear under pressure

- Advantage: Short response time when encountering unforeseen obstacles

- Robust piston

- Highly resilient

- Short machine types N

- Application in confined spaces, smaller pits

- High impact frequency

- Optimum ground penetration power

- Corrugated casing

- More grip and stability of the displacement hammer

GRUNDOMAT ACHIEVES MORE…

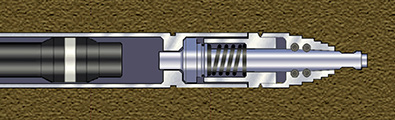

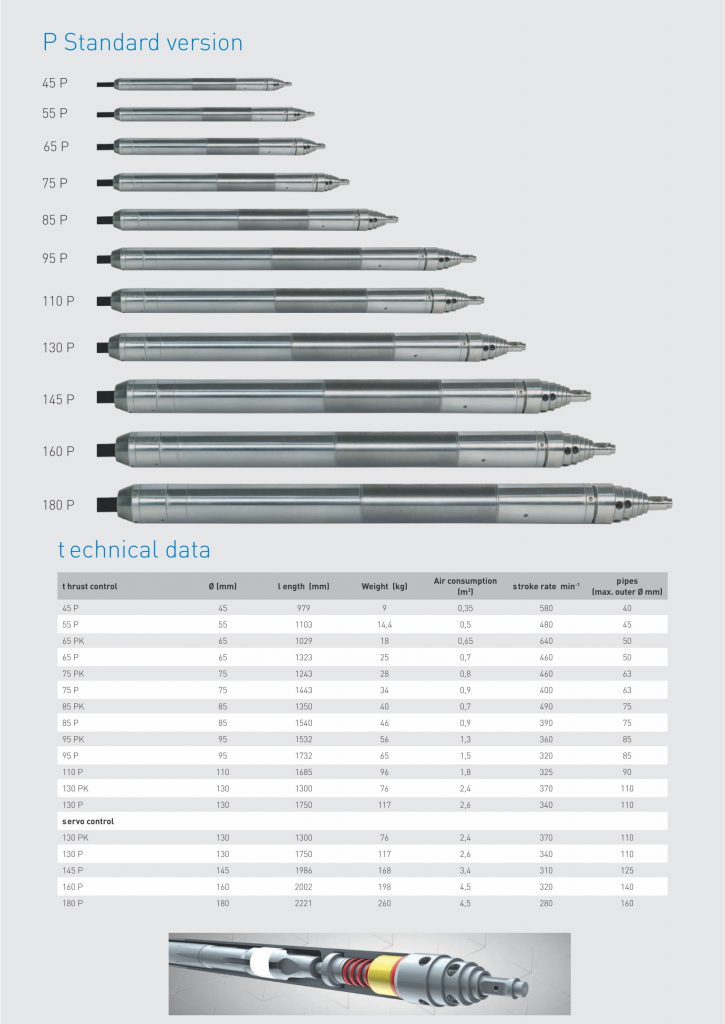

GRUNDOMAT P Series

Stepped Head

The proven stepped head is universally applicable in all displaceable soils. The chisel bores forward and opens the ground. Step by step the head then penetrates into the ground and works its way forward with great precision. The penetration process is carried out in steps which guarantee a high running stability.

The head work is carried out in 3 working steps:

- Pre-stroke

- Pulverizing

- Penetration

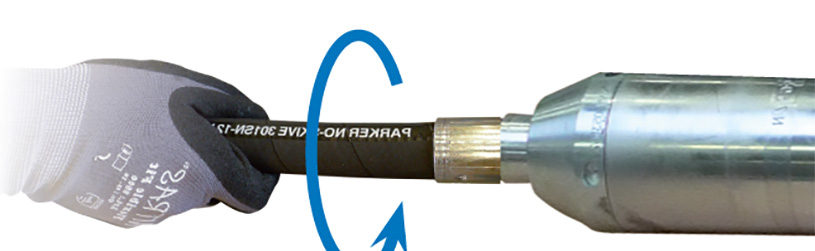

Easy switch-over: simply turn the compressed air hose a ¼ turn to the left.

- Under compressed air from forward gear to reverse gear

- Less pressure from reverse gear into forward gear

SHARE THIS PAGE